How important is clean hydraulic fluid? Very important. Of all the oil-lubricated systems in commercial and industrial facilities, hydraulic systems are, by far, the most sensitive to contamination.

How important is clean hydraulic fluid? Very important. Of all the oil-lubricated systems in commercial and industrial facilities, hydraulic systems are, by far, the most sensitive to contamination.

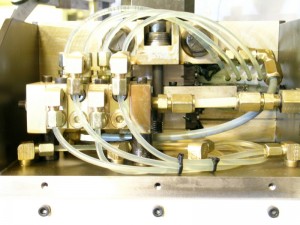

Hydraulic systems are particularly susceptible to dirty fluid problems because of all the moving parts that are often operating in the dirtiest, harshest conditions. Hydraulic systems are typically subjected to hard use and feature very tight tolerances to help keep out the bad stuff. That means when dirt and debris from wear and tear get into the system, they can cause a lot of damage quickly. From pumps to valves, cylinders to motors, hydraulic system depend on clean oil to keep running smoothly and even the smallest particle or drop of water can cause big problems.

While there is an enormous variety of hydraulic systems designed for hundreds of different applications and industries, they all have some common features regarding the hydraulic fluid power system, such as the reservoir. A well-designed hydraulic reservoir enables contaminants to fall to the bottom of the tank or be removed by a filtration system that can be installed. But a poorly-designed reservoir can feature a too-small tank that can’t adequately handle the hydraulic fluid flow or return lines that are too close and have poor baffling, setting the system up for contamination problems and possible failure.