How important is clean hydraulic fluid? Very important. Of all the oil-lubricated systems in commercial and industrial facilities, hydraulic systems are, by far, the most sensitive to contamination.

How important is clean hydraulic fluid? Very important. Of all the oil-lubricated systems in commercial and industrial facilities, hydraulic systems are, by far, the most sensitive to contamination.

Hydraulic systems are particularly susceptible to dirty fluid problems because of all the moving parts that are often operating in the dirtiest, harshest conditions. Hydraulic systems are typically subjected to hard use and feature very tight tolerances to help keep out the bad stuff. That means when dirt and debris from wear and tear get into the system, they can cause a lot of damage quickly. From pumps to valves, cylinders to motors, hydraulic system depend on clean oil to keep running smoothly and even the smallest particle or drop of water can cause big problems.

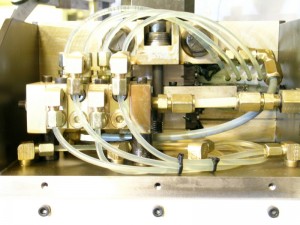

While there is an enormous variety of hydraulic systems designed for hundreds of different applications and industries, they all have some common features regarding the hydraulic fluid power system, such as the reservoir. A well-designed hydraulic reservoir enables contaminants to fall to the bottom of the tank or be removed by a filtration system that can be installed. But a poorly-designed reservoir can feature a too-small tank that can’t adequately handle the hydraulic fluid flow or return lines that are too close and have poor baffling, setting the system up for contamination problems and possible failure.

Pumps can also be a source of potential problems. Lower-pressure systems equipped with gear pumps usually do not have issues because they’re fairly forgiving when it comes to dirt and debris. However, tight-tolerance vane and piston pumps are not as tolerant of contaminants, especially in high volume pumping situations. Their tight clearances mean they have much lower tolerances for contaminants.

Flow control valves are another place for possible problems. Complex, servo-controlled hydraulic systems can be highly sensitive to contamination, especially when valve dwell times are long. Simpler systems such as those with check or directional valves can take a lot more abuse and tolerate dirtier hydraulic fluid.

For particle contamination, the big concern is silt-sized particles in the 1-micron to 10-micron size range. While tiny — less than 1/10th the thickness of a human hair — 3-micron silt-sized particles, which are no bigger than a red blood cell, are as much as five to ten times more likely to cause failure. That’s because many filters are not designed to remove such small particles, coupled with the fact that dynamic clearances (the separation between moving parts under operating load, speed, and temperature) in pumps and valves are typically in the 1-micron to 5-micron size range.

After hard particle contamination, water is the second most damaging contaminant found in hydraulics. Present in most fluids even in the cleanest environments, water can increase failure rates 10-20 fold depending on circumstances. Water causes problems in a number of ways — first, any iron or steel surface in contact with water will, of course, start to rust. This can induce premature failure due to corrosion, as well as introduce rust particles into the fluid.

So it’s clear to see that contamination can be a big problem for hydraulic systems – it’s critical that hydraulic fluid be checked regularly and systems kept clean and dry. A well-designed hydraulic system is generally trouble-free, but even the best system can run into problems if operated for any length of time in less-than-optimal conditions with hydraulic fluid that’s allowed to build up contaminants.